Fuel Still Plans "Build-it-Yourself"

Ethanol Distillation

Ethanol fuel is made from sugar in plants like corn and rice. With fuel still plans, you can create a much cleaner, and greener motion potion for your vehicle and other combustion powered devices.

Biodiesel Fuel

The same goes for biodiesel which is created through the process of recycling restaurant grease. That's right! oil used to make our french-fries nice and crispy can also be used as powerful bio-fuel.

Cleaner and Greener Fuel Still Creations

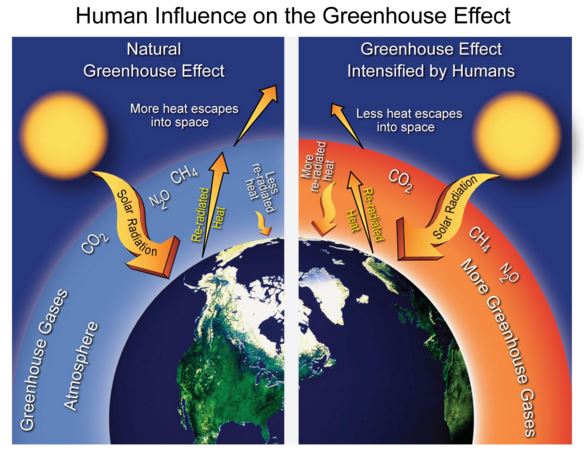

We are surrounded by it everyday, yet we are ignoring the harmful effects on our environment from petroleum fuel use. Gasoline and diesel fuels are emitting hazardous gasses into our atmosphere. This in turn fuels the warming of our planet and the greenhouse effect.

By reducing our use of petroleum fuels, and moving toward enhanced use of ethanol and biodiesel bio-fuels, we could reduce the air pollutants we subject our planet to significantly.

Bio-fuels have proven to be a good source of alternative energy for many who resort to producing their own fuel with corn crops and the like. The process of making biofuels with a still can be quite easy with the right set of fuel still plans.

When you see how the Greenhouse Effect changes our atmosphere, it's easy to get worried about the long term effects to come.

Therefore, it should be a consideration we all partake in to find and initiate cleaner and greener practices for our planets health.

While it may not be a big concern to many of us now, those generations to come will be effected.

Benefits To Producing and Using Bio-fuels

- Grain alcohol (ethanol) is renewable energy

- Green output, products of combustion are water and co2

- Affordable to make with your own fuel still at home

- By-products of bio-fuel production are useful

- It takes 56 lbs of mixed grain to make 5 gallons of “farmer’s alcohol.” This leaves 26 lbs of leftover mash that contains more nutritional value than in the original grain! Therefore, animals feed can be enhanced on the farm with this leftover “by product”.

Homemade Ethanol: Producing Your Own Fuel

You can produce your own clean-burning alcohol fuel in your own backyard, as many people do. Homemade ethanol producers are running their vehicles on this instead of gasoline. Fact is, you can even build your own still for that exact purpose.

First things first, you will need a alcohol fuel permit to do this legally in the United States. No worries, fact is they are very easy to get.

Next, you will need a still to ferment beer, or wine, from corn, barley, molasses, or even kitchen scraps. Important advice, don't tell your wife that's what you did with the dinner she cooked you!

Building a True Reflux Still With Fuel Still Plans.

When

your ready to jump into ethanol fuel production, you'll need to decide if you want to buy,

or build a still with some Fuel Still Plans for this purpose.

When

your ready to jump into ethanol fuel production, you'll need to decide if you want to buy,

or build a still with some Fuel Still Plans for this purpose.

A reflux still is the proper tool for the job

Reflux refers to the up and down action inside the still column where the alcohol and water vapors are condensing and re-boiling. This process is what successfully separates pure alcohol from the water.

A properly constructed reflux still has the column and condenser temporarily attached to the boiler. This is important for properly controlling the temperature, which is how you control how high the proof is by means of raising or lowering the boiler temperature.

Reflux Still Components and Construction

The distillation column should be a separate and easily controlled component. This will make the production process much easier to manage, insuring that the final product is 160 to 180 proof instead of a measly 100 to 120 low potency instead.

It's important that your reflux still column is internally packed with a packing material that is thermally stable. Large reflux columns in commercial still operations often use ceramic marbles or raschig rings for this purpose.

Raschig rings are pieces of tubing that are approximately equal in length and diameter. They are used in large numbers as a packed bed inside reflux columns for distillation. Usually made of ceramic or metal, they provide a large amount of surface area within the volume of the column for interaction between liquid and gas or vapor.

Raschig rings are named after their inventor, German chemist Friedrich Raschig, as they are also used in chemical engineering processes.