The Secrets of Building an Alcohol Producing Still

1994

Publication.

1994

Publication.

by:

- Vincent R Gingery

1964 Out of Print = pdf ebook

Format: .pdf

Download: 16.0mb

Contents: 84 pages

Preface: The Secrets of Building an Alcohol Producing Still

Having made my own wine, beer and even soda pop for the last several years, I have become fascinated by the entire process involving the action of yeast on sugar. I guess that it is only natural that I would progress to the point of actually wanting to distill the alcohol from the beer and/or wine product.

TABLE OF CONTENTS

7: THEORY OF DISTILLATION

8: STILL DESIGN

11: APPLYING FOR YOUR ALCOHOL PRODUCERS PERMIT

13: ALCOHOL A HISTOFtiC 13AC1CGROUND

16: MAJ(ING YOUR OWN MALT

17: 13UILDING THE SPROUTING TRAYS

19: DRYING THE SPROUTS

20: GRINDING THE MALT

20: MASHING

22: YEAST STARTER

22: THE RECIPE

26: FERMENTATION

28: OLD WAYS VERSUS THE NEW

31: HOW THE MOONSHINERS DID IT

35: MATERIAL LIST

36: TOOLS NEEDED

36: CONSTRUCTION METHODS

41: 13UILDING THE INNER TAN'K

44: BUILDING THE OUTER TAN'K

46: INSTALLING THE HEATING ELEMENT

48: PUTTING THE TWO TANKS TOGETHER

52: MAKING THE CONE

55: SOLDERING THE CONE TO THE INNER TANK

55: MAKING THE RECTIFYING COLUMN

60: MOUNTING THE INFINITE RANGE SWITCH AND ELECTRICAL BOX

65: WIRING

66: BUILDING THE CONDENSER

69: CONNECTING THE CONDENSER TO THE STILL

73: PREPARING THE STILL FOR THE FIRST RUN

77: ALCOHOL AS A MOTOR FUEL

82: SUPPLIER LIST

82: BIBLIOGRAPHY

INTRODUCTION

In the next few paragraphs I will give a brief description of the steps we will take in producing alcohol and an overview of the still design. To begin with, we will discuss applying for and getting your experimental alcohol producers permit from the Bureau of Alcohol, Tobacco and Firearms. This is a simple process and it only takes a few days to get a permit.

The second step of the alcohol producing process is ,called malting. The process includes sprouting and drying grain. Once a grain is sprouted and then dried it is said to be malted. The sprouting stage of the grain converts nonfermentable starch to fermentable sugar. Sprouting also produces enzymes in the grain which further aid in the starch to sugar conversion process. More about this later. There are two ways to get the necessary malt required for the conversion process. The easiest way would be to buy your malted grain from someone who sells wine and beer supplies. If you buy malted barley, make sure it has all of the necessary enzymes needed for conversion. Some specialty malts do not contain them. The other option would be to make your own malt. This is really a very simple and inexpensive process, but it is time consuming. The grain I used for making my malt was corn. The reason I use corn is because it is easier to find at the feed store. Although barley is the preferred, corn works just fine .

If you choose to make your own malt the first stage of the malting process is sprouting the grain. To do this we must create an acceptable environment for the seeds. Later on in the book I will show you how to build a small 10 layer sprouting bin to make the sprouting process easier. Each layer of the sprouting bin consists of a simple rectangular box made of 2x2 lumber with a screen bottom for drainage. Each sprouting bin holds 1 pound of grain.

The second stage would be the drying process and it takes about four days. Three ways of drying your grain will be discussed. After the grain has dried, it will be necessary to separate the sprouts from the malted grain. Once cleaned and separated, the malt is stored in a dry place until it is needed. Just before it is needed, it is ground to a fine meal to further expose the starch granules thus making it easier to turn them into sugar.

The third step is mashing. In this step all remaining starches are converted to usable sugar. Yeast can only ferment sugar. This is accomplished by mixing a measured amount of water, malted grain, and in this case ground corn together. The mixture is heated in stages. Heat is held at each stage for a specific length of time and at a specific temperature. When all of the starch in the grain is converted to sugar the mixture is strained through a strainer bag. After the mash is strained there will be some sugar left on the grain. To get all of the available sugar from the grain we pour hot water over it. This is referred to as rinsing. The liquid that remains is called beer, or wort. The spent grains are used for livestock feed or fertilizer for the garden. When the mashing process is complete the temperature of the wort is allowed to drop to 80 degrees at which time a yeast starter is added. The yeast starter solution is made a day ahead of time and consists of sugar, yeast, juice and a small amount of wort. The fermenting process takes about a week to ten days.

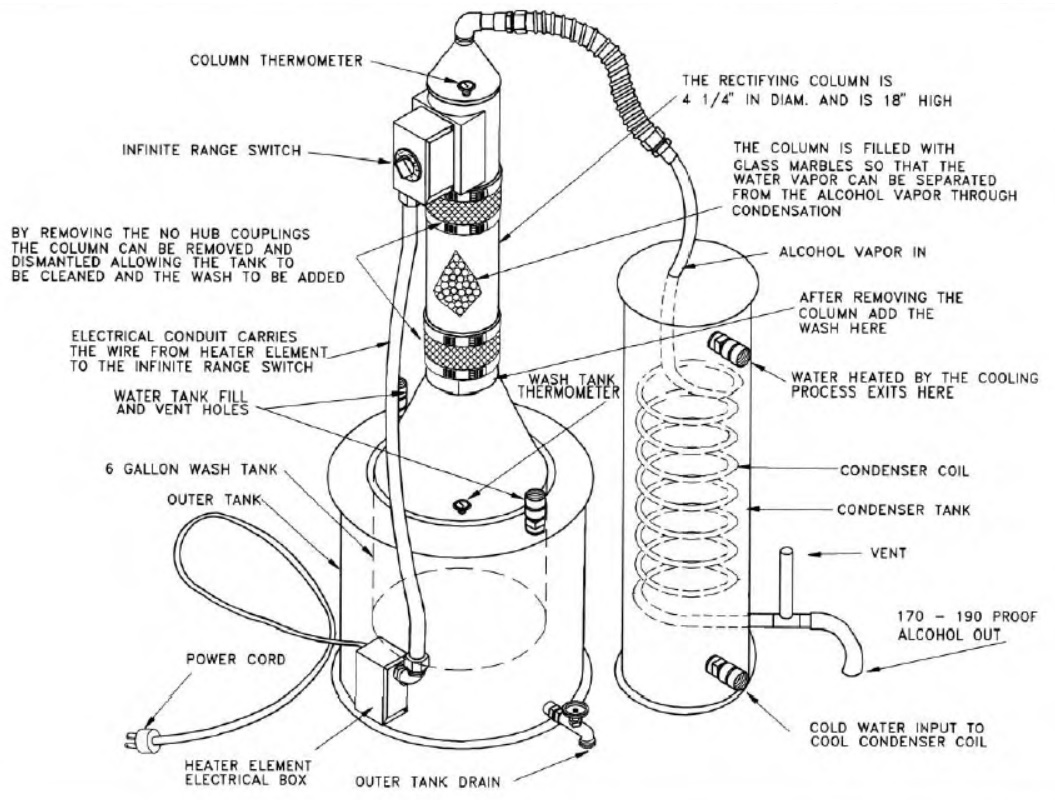

The theory of distillation; You may refer to the detailed drawing on page 10 as we discuss the operation and construction of the still......

God Speed in turning your pdf downloads into working stills